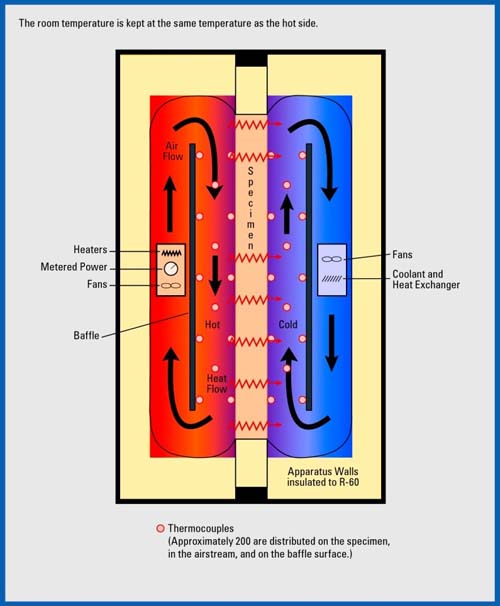

A Hot Box is a specially-calibrated instrument in the Home Innovation building product testing lab designed to measure heat flow for large building specimens. The hot box has two sides as illustrated in the diagram below: the hot (red) side with an electric resistance heater; and the cold (blue) side with a heat exchanger connected to a chiller. A fan circulates air on each side as shown by the arrows in the schematic. The building system (wall, ceiling, roof, etc.) to be tested goes between the hot and cold sides and the entire Hot Box is placed in a heavily insulated room that is heated to the same temperature as the hot side of the Hot Box. The energy input to the hot side is precisely measured for both the power to the heater and the power to the circulating fan. Direct current (DC) power is used to power both the heater and the fans as DC current provides a more accurate measurement of the power input. Approximately 200 thermocouples measure air and surface temperatures on both sides of the Hot Box.

Schematic of Home Innovation’s ASTM C1363 Hot Box.

As we know from the Second Law of Thermodynamics, energy moves from hot towards cold. So once we know the temperature difference across the test specimen and the heat flow, we can calculate the R-value or U-value.

The key to an accurate result is correctly measuring the heat input to the hot side and ensuring that all the heat goes from the hot side to the cold side and that none either leaks out of the Hot Box or bypasses the test specimen. To adjust for any energy that goes through the Hot Box walls or tries to bypass through the specimen frame, we calibrate the box. Calibration consists of running a test specimen that has a known R-value — typically a rigid foam board with the R-value measured by ASTM C518 — and comparing the calculated heat flow for the known R-value to the heat input into the box. The box has a heat flow meter consisting of two thermopiles built into its walls. The heat flow meter reading is proportional to the amount of energy not going through the test specimen. By running multiple conditions, we develop a calibration curve and use it to provide accurate results.

The Hot Box at Home Innovation Research Labs is one of the largest available nationwide. It accommodates test specimens up to 9 feet by 16 feet. In this type of testing, bigger is definitely better. A larger Hot Box has a better area/perimeter ratio, which means greater confidence in the results. Home Innovation’s Hot Box can also be rotated so the specimen can be tested vertically as a wall, horizontally as a floor or ceiling, or pitched to simulate a cathedral ceiling.

We conduct testing per ASTM C1363 and ASTM C1224 in the Hot Box.

With increasingly stringent energy codes, product manufacturers and builders are developing new products and innovative construction techniques to improve the home’s thermal envelope. Code officials and designers want R-value data they can count on, but without testing, the R-value of the assembled component is unknown. Hot Box testing is a reliable way to capture shareable, marketable data that is a superior to data gathered via modeling.

Consider the typical residential wall, which consists of a wood frame with fiberglass insulation between the studs, sheathing, a weather resistive barrier, drywall on the interior walls, and exterior siding. Many high performance wall systems now also have a layer of rigid foam. In this somewhat typical scenario, three factors complicate the R-value calculation. First, each building component’s contribution to the overall R-value of the system is different. Second, each building material has different thermal conductivity and some materials, especially the wood framing members, are not uniformly distributed through the assembled wall system. Finally, heat flow in this scenario is a three-dimensional phenomenon. It's easy to model one-dimensional conductive heat flow, but modeling three-dimensional heat transfer is much more difficult and less reliable. Further, some of the modeling parameters, such as contact resistance between the various layers, are difficult to establish accurately for modeling. The Hot Box removes any concerns that modeling parameters and assumptions are incorrect because the test is conducted on actual wall or ceiling specimens, allowing our building science experts to determine the answer with a high degree of confidence.

A wide variety of materials and systems have been tested in our Hot Box ranging from a typical wood-framed wall, to a reflective system, to metal building roofs, to floor systems, and masonry systems. We'd be happy to work with you to conduct custom thermal testing for your residential building system. To learn more about how Hot Box testing can help your success in the market, contact us.